Sanitary Valves

A wide selection to give you optimal performance and profitability.

Alfa Laval Master Distributor

The need for efficient and reliable product flow is critical to your performance and profitability. You need optimal flow throughout your process to get the most out of your raw materials. Having the right valves in place is key. We’ve been supplying valves and valve automation for more than 40 years. We are an Alfa Laval Master Distributor and carry a large, in-stock selection so we can quickly meet your needs.

Our line of Alfa Laval valves offers:

• Highest levels of hygiene

• Intelligent reliability

• Easy installation and maintenance

• Low cost of ownership

• Lower environmental impact

Product Literature >

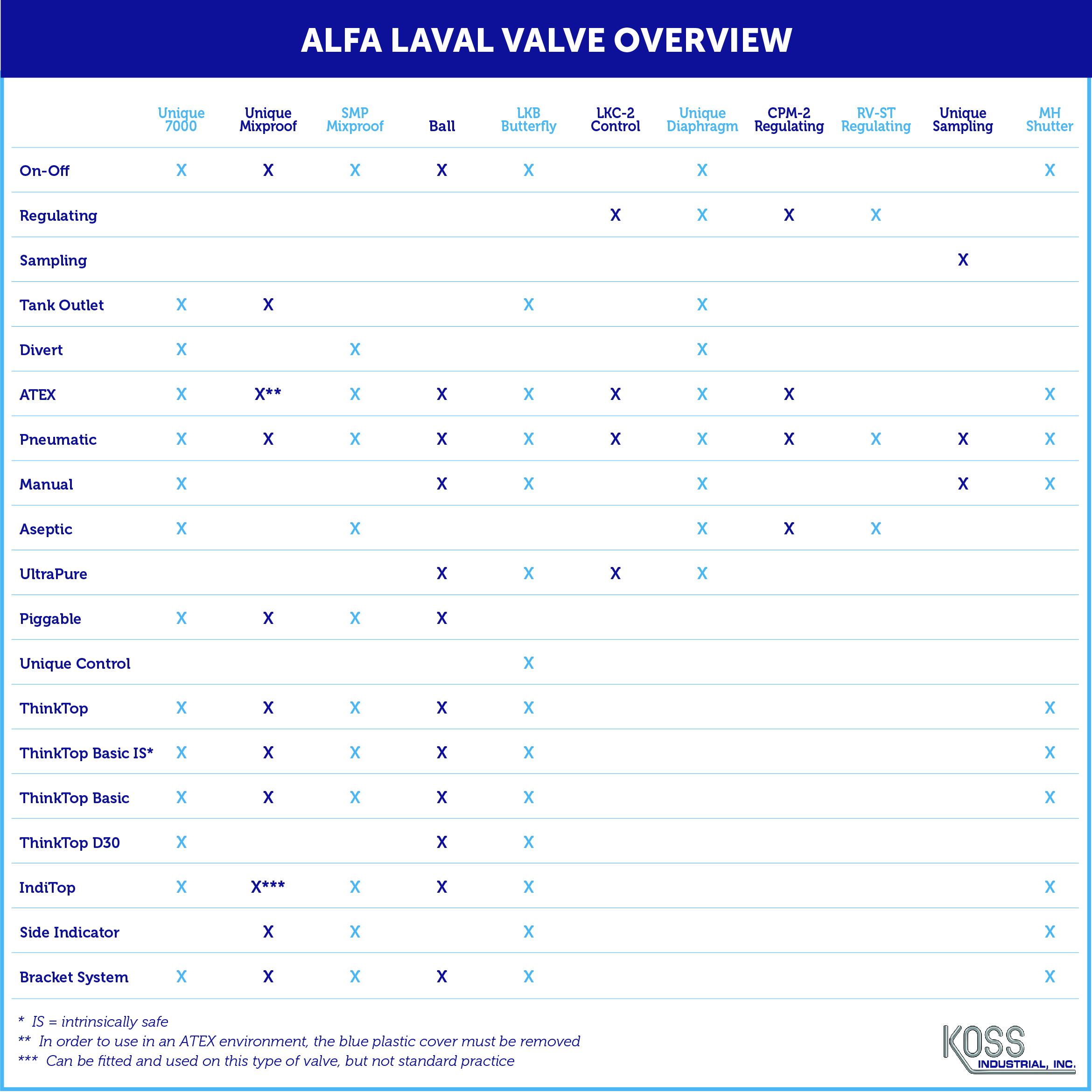

Choose from the following valve options:

Different Types of Sanitary Valves

Single Seat Valves

Alfa Laval's range of single seat valves consists of large numbers of purpose-designed valve units that are very robust and flexible. They are ideal for use in processes with a high hygienic standard.

These valves can go by many names depending on their application: divert, shut-off, and changeover to name a few.

The Unique 7000 series offers a variety of changeover and shut off valves including, aseptic, long-stroke, manual, reverse-acting, tangential, tank outlet, two step and Y-body models.

Alfa Laval's 700 series is a broad series which includes divert, long-stroke, shut-off, tangential, tank outlet, throttling, Y-body and changeover models. All are 3-A symbol authorized.

The SB Mini Flow series is ideal for when hygienic shut-off or changeover of liquids or gases is required.

Large variety of purpose-designed valves

Robust and flexible

Ideal for high-hygienic applications

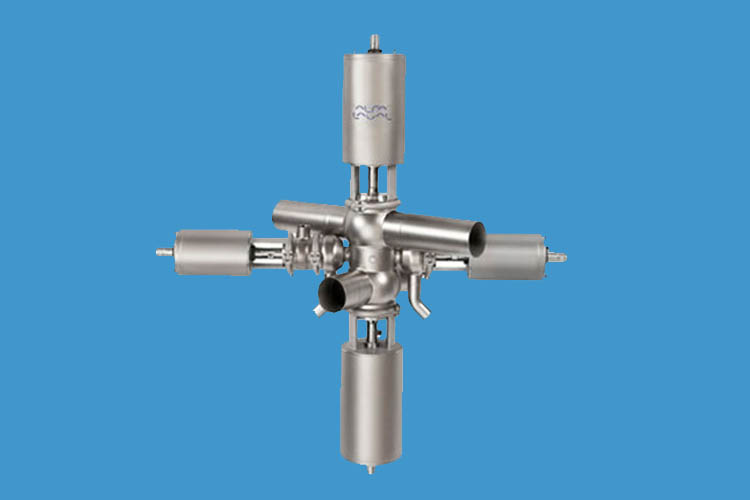

Mixproof Valves

Mixproof valves are designed to allow two products to flow through the valve at one time without risking cross-contamination. They have two independently controlled valve stems and are ideal for automating pipeline processes in dairy, food and beverage applications.

Double-seat models can do the work of two or three single-seat valves which provides initial installation cost savings as well as saving on space.

Alfa Laval's standard, cost-effective, double seal models are found in its SMP series.

Double seat models include the Aseptic Mixproof series, for sterile process applications, and the Unique Mixproof series which has different models covering a variety of applications including PMO and 3-A compliance, large particulate and high-viscosity fluids, and tank-specific applications.

Two fluids flow through one pump

No cross-contamination

Ideal for dairy, food and beverage

Ball Valves

Alfa Laval's ball valves are constructed with a full-flow body design, enabling the product to pass through the valve with no restrictions and with a minimal pressure drop. The basic design allows cleaning and product recovery using pigging systems, and they are ideal for use with viscous liquids and liquids containing solid or semi-solid particles.

The 5308/5309 series valves are designed for use as product valves.

The SBV series features full-bore flow valves that provide on/off control with minimal pressure drop.

Full-flow design

Minimal pressure drop

Ideal where pigging systems are used

For viscous liquids and those with particulates

Butterfly Valves

Butterfly valves are straightforward on/off routing valves with a substantial opening area and low flow resistance. They are an optimal solution in modern processing technology and ideal for use with low and medium-viscosity liquids.

Alfa Laval's LKB series consists of a variety of modular units that can easily be mounted in complex cluster set-ups alongside valves of other types. Models for ISO and DIN connection.

The LKB UltraPure series consists of hygienic on/off valves for use with low and medium-viscosity liquids in personal care, biotech and pharmaceutical applications.

The LKB-F models are made for flange connections for easy removal of the valve body without dismantling piping setups. For both ISO and DIN.

On/Off routing valves

Low flow resistance

For low and medium viscosities

Control / Check Valves

Alfa Laval's control/check valves (sometimes called non-return valves) are highly reliable valves used to ensure single directional product flow through process lines. This provides protection for process equipment that can be affected by reverse flow and prevents pressure surges and/or system shutdowns.

The LKC series offers models of non-return valves specially designed for stainless steel piping and UltraPure models for biopharm and personal care industries.

LKUV-2 models are air-relief valves.

The SB Self Cleaning CO2 models are ideal for managing CO2 flow and enable tanks to be vented or pressurized while minimizing gas consumption.

Ensure single directional flow

Multiple uses

Diaphragm Valves

Alfa Laval's Unique DV-ST UltraPure series offers a wide range of diaphragm valves that are built on a modular design and can be configured to meet to any specific requirement. Ideal for use in sterile and ultra-hygienic processes and supplied with a comprehensive documentation package, providing full transparency of sourcing, production and supply chains, and traceability of all changes in material, manufacturing procedures or spare parts.

Modular design

Highly-configurable to meet variety of needs

For sterile and ultra-hygienic processes

Transparency and traceability

Regulating Valves

Regulating valves are used for adjusting or monitoring flow volumes and flow directions. Specially designed for use in a broad range of metering, blending, weighing and filling system applications, they are the ideal solutions for precision control of flow rate or pressure.

Alfa Laval's CPM series valves are pneumatic valves that maintain a constant inlet or outlet pressure in hygienic process lines.

The SB regulating series has models for regulating pressure in the brewery, food, dairy and beverage industries.

Alfa Laval's Unique RV series has models ideal for high-volume sanitary liquid processing as well as plug valves.

Adjust or monitor volume and direction

Precise control of flow rate or pressure

Safety Valves

Safety valves are used for overpressure or vacuum protection in tanks and pipelines. They protect against implosion due to vacuum caused by cold rinsing after hot cleaning; against implosion due to caustic absorbed in CO2 atmosphere/temperature fluctuations or against implosion due to blocking of gas supply during emptying.

The SB safety series offers anti vacuum and pressure relief models.

Alfa Laval's Safety Valve series guards against overpressure in tanks and vessels.

Overpressure or vacuum protection

Protect against implosion in tanks and pipelines

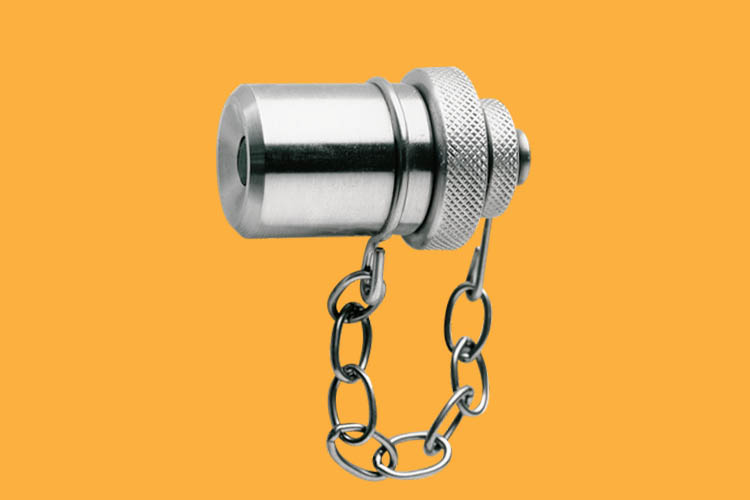

Sampling Valves

Sampling valves make it possible to obtain representative samples of dairy, food, beverage, personal care and biopharm products.

The SB sampling series offers models that allow for large or small volume gathering of representative samples from tanks and pipework.

Alfa Laval's Unique Sampling Valve series has single and double-seat sampling valves.

Allow product sampling from process line

Shutter Valves

The Koltek MH series from Alfa Laval is a manually or pneumatically operated valve designed for use in industries where sanitary designs are required. Designed for difficult applications, these valves provide several application options and are ideal for fluids with large particles, high viscosity, or where pressure loss must be minimized.

Handle difficult applications

Ideal for high-viscosity fluids

Ideal for product with large particles

For when pressure loss must be minimized

Additional Resources

Viscosity

Viscosity is defined as a fluid's resistance to flow. The thicker the liquid, the higher the viscosity.

It is important to protect the integrity of the fluid being processed by choosing the correct valves. Valves used with higher-viscosity products tend to be larger with longer stroke actuators, which reduce pressure drop and shear on the product. Large, open throat valves provide gentle product handling and allow particles up to about 1.5 inches to pass through.