Cheese Extruders & Molders

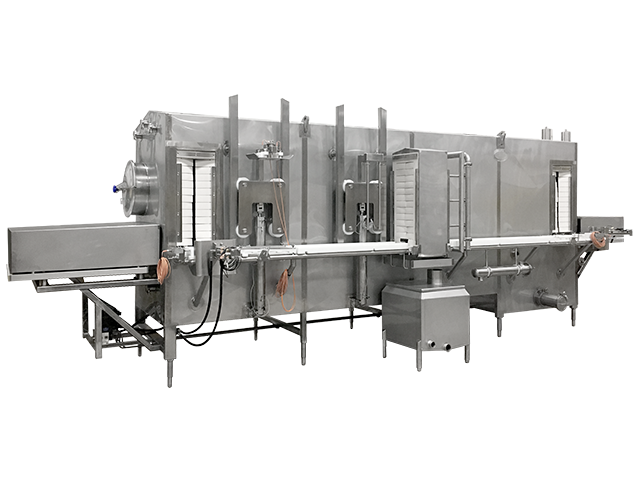

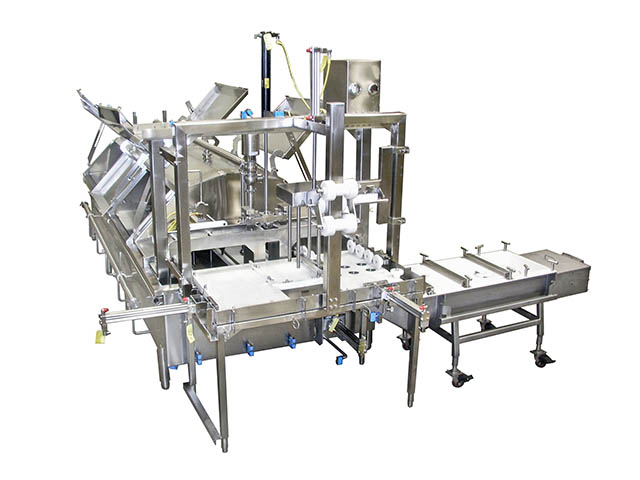

Automated Molder Chillers (AMCs)

Your pasta filata cheeses won’t adhere to the non-stick surfaces of our custom-built, stainless steel automatic molder chillers. In addition, these units can also operate as cheese block formers.

- Complete hands-free automation

- Can be spray or immersion based

- Choose from rotary or shuttle styles

- Create consistent shapes time after time

- Create different product weights without tooling changes

- CIPable options for easier, effective cleaning

Meet or exceed USDA sanitary standards.

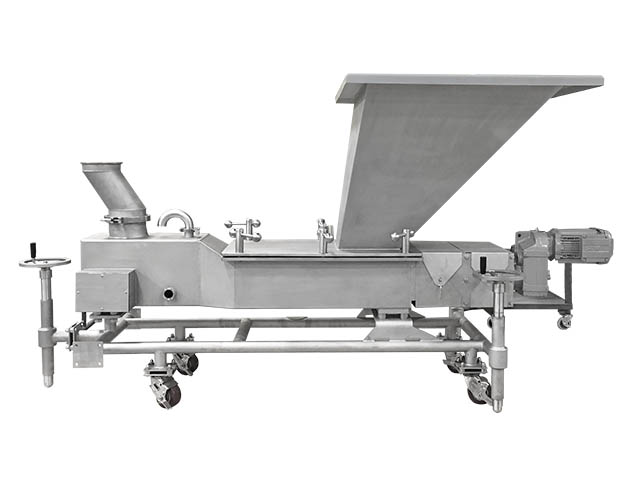

Cheese Extruders / Molders

Get your pasta filata cheeses from cooker to mold in a custom-built stainless steel extruder from Koss.

- Can be mobile or stationary

- Multiple styles of shuttle heads and string extrusion heads available

- Completely jacketed unit

- Heavy-duty gearboxes are easily serviced

- Can be made CIPable for easier, effective cleaning

Options include:

- Hydraulic or electric drive motors

- On-board hot water set

- Electric heat

- Jacketed infeed hopper

Meet or exceed USDA sanitary standards.

Product Literature >

For further reference ...

More about cheese extruders / molders

Extruders transfer pasta filata cheeses from cooker to mold. They add the finishing grain structure to pasta filata cheeses (such as Mozzarella, String, Provolone and Oaxaca). Pasta filata cheeses become elastic when heated and are known for their stringy, stretchiness. They are the ideal pizza cheeses.

Used between the cooker and mold

Used in pasta filata cheese production

More about automated molder chillers (AMCs)

After the curd of pasta filata cheeses has been heated and stretched, it is molded at an elevated temperature. Molders shape the curd into uniform pieces. For Mozzarella-style cheeses and Provolone, the molded cheese is typically immersed in cold water, cooled in brine, and packaged. Additionally, Provolone is often ripened or aged and in some cases smoked.

Molding takes place while cheese is hot

It's then cooled in water/brine

Used in pasta filata cheese production

More about pasta filata cheeses

Pasta filata cheeses are a group of stretched-curd cheeses, mainly of Italian origin. During manufacture, the curds are dipped into hot water and then stretched or spun until the proper consistency and texture is achieved. The curds are then kneaded and molded into the desired shapes. Pasta filata cheeses are known for their excellent stretch and elasticity when melted making them great additions to pizzas and other baked dishes.

Examples include Mozzarella, Provolone and Oaxaca (wuh-HAH-kuh).

They share a common manufacturing process

Curds are heated and stretched

Known for their elasticity when melted