Custom Fabrication & Finishing

If you value decades of experience, superior craftsmanship and attention to detail, our talented and dedicated team can deliver.

Custom Fabrication & Finishing

Experience and attention to detail are critical when every piece of equipment is unique. Custom fabrication requires a skilled and talented crew dedicated to quality craftsmanship. Our engineering and fabrication teams work closely to ensure equipment is designed and built to the highest of standards.

Finishing is a critical component to any metal fabrication project. As the final step in preparing metal products for use, finishing impacts a product’s appearance and durability and provides corrosion resistance. We provide a wide range of finishing techniques for flawless results.

Metal Cutting

We are experienced in a variety of metal cutting processes including:

- Sawing

- Shearing

- Punching

- Notching

Polishing, Blasting & Deburring

We are skilled in the following areas:

- Mirror finishing

- Color cleaning

- Glass bead blasting

- Sand blasting

- Vibratory deburring

Acid passivation and Teflon coating services also available.

Rolling & Forming

We feature a variety of custom rolling and forming services.

- Angle rolling

- Channel rolling

- Pipe and tube rolling

- Bar rolling (solid and T)

- Sheet plate rolling and forming

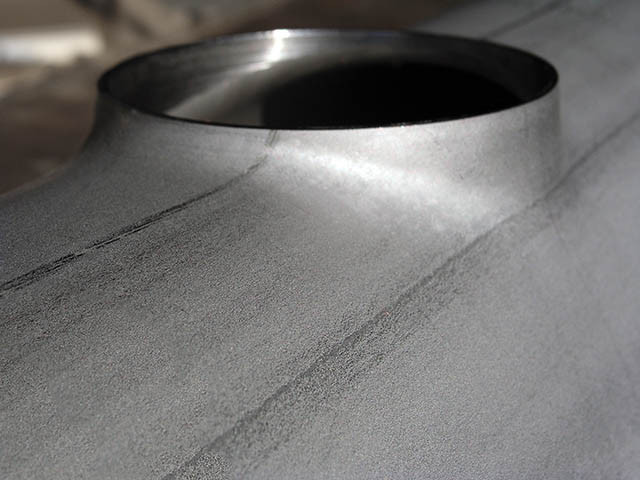

Tube & Pipe Branching

Our capabilities include branch connecting using a cold forming pulling process. Using one machine, ports are pulled to size then welded.

- Most effective method for tubing fabrication

- Significantly reduces number of joints in a pipe run

- Lowers material costs

- Reduces fabrication time

- Limits material handling

- Nearly limitless orientation and location options

- Limits thermal fatigue of materials

Ideal for most malleable materials including stainless steel, carbon steel, copper, copper-nickel and aluminum alloys.

Welding

Koss is recognized by the American Welding Society in the following areas:

- AWS D18.1 - Welding of austenitic stainless steel tube and pipe in sanitary (hygienic) conditions

- AWS D18.2 - Weld discoloration inside austenitic stainless steel tube

- AWS D18.3 - Welding of tanks, vessels and other equipment in sanitary (hygienic) applications

We handle spot welding, brazing and soldering and have MIG/TIG, purge, heli arc, spray arc, wire feed, and orbital welding capabilities.

Equipment Capabilities

Heli-Arc, Spray-Arc and Wire Feed

Orbital tube welding up to 4" diameter

CNC crowning

5 axis backgauge

Capacity = 110 ton x 12' bed

Single axis backgauge each

Single axis backgauge

Round Capacity = 10.75"

Full mitering capabilities

One saw has swivel capabilities

Material Size = 1/4" thick x 12' wide (stainless steel)

48" backgauge travel

1 inch mild steel capacity

Tube and bar polishers - 6" maximum diameter