Sanitary Washers

Cabinet Washers

Koss cabinet washers are designed and manufactured for efficient, automated batch cleaning while lowering operating expenses. Sanitary spray assemblies distribute cleaning solution evenly throughout the entire washer, efficiently removing difficult residues from both interior and exterior product contact surfaces.

- Programmable logic controller (PLC) for a repeatable and documented process

- Ideal for bins, buckets, buggies, meat sticks, pans, product carriers, totes, trays, vats and more

- Heavy-duty stainless steel construction

Meet or exceed USDA sanitary standards.

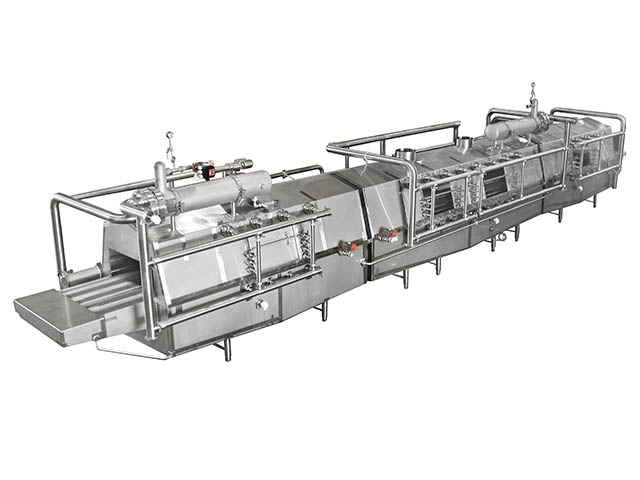

Tunnel Washers

Quickly clean high-volume processing components such as barrels, buckets, freezer spacers, hoops and molds, pallets, pans, totes, trays and more. Our tunnel washers can provide detergent, pre-rinse, recirculated rinse and final rinse zones depending on your product residues and capacity requirements.

- Reduce labor costs and cleaning time

- Minimize and control chemical usage

- Lower your water and utility costs

- Heavy-duty stainless steel construction

Meet or exceed USDA sanitary standards.

For further reference ...

More about sanitary washers

Sanitary tunnel and cabinet washers can be used in a variety of industries such as dairy, beverage, brewery, bakery, confectionery, distilleries, meat and poultry, snack foods, and sauces and slurries. Both are a faster, more efficient way of cleaning and sanitizing high-volume processing components compared to manual washing.

Koss sanitary tunnel washers are conveyored systems. Think of them like car washes for industrial processing components. The items being washed move along the conveyor through different wash cycle chambers.

Koss sanitary cabinet washers are like industrial size dishwashers that you load, close for cleaning and sanitizing, and then unload.

More efficient than manual washing

Tunnel washers operate like car washes

Cabinet washers operate like dishwashers