Custom Food and Beverage Processing Equipment

Big and small, we do it all

From individual components and equipment, to complete process lines, to full-plant installations, Koss brings more than 40 years of knowledge and experience to the table.

- Cheesemaking equipment

- Dairy processing equipment

- Food and beverage processing equipment

- Expertise in custom sanitary stainless steel fabrication

- Engineering and design of new equipment and systems

- Food contact grade and food safe designs

- Repairing, refurbishing and enhancing existing equipment and systems

When it comes to providing you with safe, long-lasting, reliable sanitary solutions that will provide value for years to come, Koss has the know-how and the background to deliver, no matter how large or small your project.

Product Literature >

Blenders, Mixers & Tumblers

Koss proudly offers ribbon blenders, mixers, liquefiers, powder funnels and tumblers that are custom fabricated from heavy-duty stainless steel to your specifications.

- Request a stand-alone item or make it part of a complete processing system

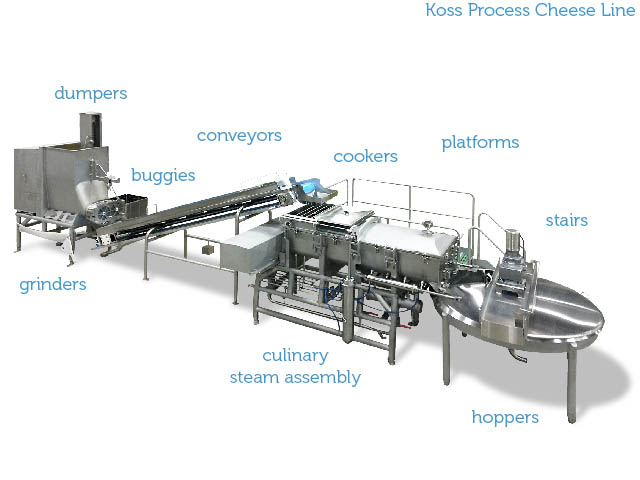

Cheese Cookers

Koss stainless steel cookers are available in a variety of styles. Some use hot water, some use steam injection and some include molding and stretching capabilities.

- Request a stand-alone cooker or make it part of a complete processing system

Cheese Cutters & Slicers

Whether you’re slicing 6 oz. logs of fresh Mozzarella or cutting 640 lb. blocks of Aged Cheddar, we can design and fabricate stainless steel cutting equipment to meet your specific production needs.

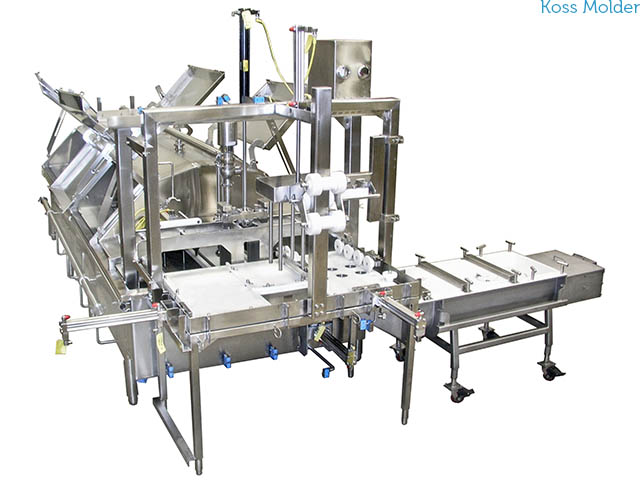

Cheese Extruders & Molders

Custom fabricated to meet or exceed USDA sanitary standards, our stainless steel cheese extruders and molding units have non-stick surfaces and are available with multiple options.

- Ideal for pasta filata cheese production

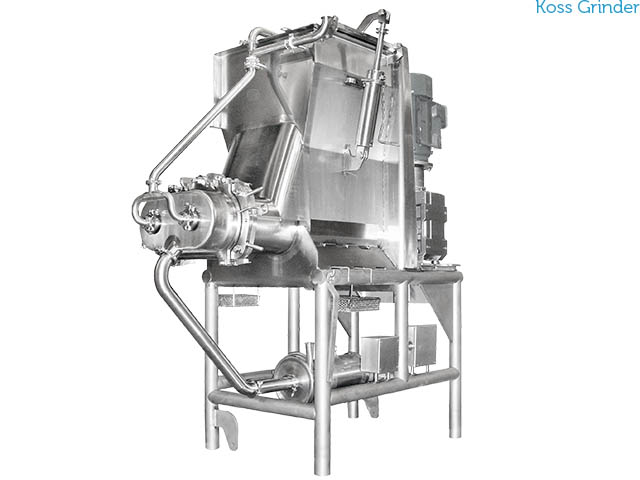

Cheese Grinders & Pre-Breakers

Koss stainless steel cheese grinders, designed and fabricated to meet or exceed USDA sanitary standards, are capable of grinding a variety of hard and soft products.

- Easy-to clean design

- Available in four different sizes to suit applications from lab to heavy production

- Custom sizes also available

And while our grinders are extremely robust, we do offer pre-breakers to reduce your starting product into more manageable sizes before grinding.

Looking to grind something other than cheese? We can custom build a grinder to fit your process.

Cheese Presses & Hoops

Koss A-frame cheese presses and hoops (or forms) work together to accomplish your cheese pressing needs. Made from stainless steel and meeting or exceeding USDA sanitary standards, you’ll love the durability of a cheese pressing system from Koss.

- We offer stainless steel Wilson-style hoops

Curd Handling

Let Koss design and fabricate stainless steel equipment for all your curd handling needs. We have more than 40 years of expertise in the cheesemaking process.

- Air lock assemblies

- Curd pails

- Curd cyclones

- Curd unloaders

Filler Machines

Add a custom built Koss filler machine to your production line. Built to meet or exceed USDA sanitary standards, our stainless steel fillers are built to last.

- Customizable by filling method (piston, valve, conveyor)

- Customizable by filling measure (volume or weight)

HTST Pasteurizers

Our custom-built HTST Pasteurizers are built to meet your particular applications and facility space requirements.

- You define the temperature and time requirements and we'll build to suit

Transfer Panels / Flow Plates

No matter the number of ports needed, Koss can engineer and fabricate a stainless steel transfer panel (sometimes called a flow plate) to allow separation of your process flows.

- Ideal for applications in the food, dairy, pharmaceutical and biotech industries

Related Items

Cleaning & Sanitation >Heat Exchange & Transfer >

Process Skids >

Product Conveyance >

Separation & Filtration >

Tanks & Vessels >