Your Source for Industrial Separators, Filters & Strainers

Filter Elements & Housings

Filtering prevents particulates (which could affect product safety, consistency and/or flavor) from infiltrating your product. We can provide a wide variety of sanitary filters and housings that best complement your flow rate and product viscosity.

Membrane Systems

It can be challenging to produce safe, quality products in a cost-effective manner. Our membrane systems help increase product quality, yield and production efficiencies while reducing costs. We'll work with you to design a processing filtration product that meets your specific needs. Each of our custom-built membrane systems is available in a variety of sizes and configurations.

- UF - Ultrafiltration systems (including the Koss ClearBrine™ unit)

- MF - Microfiltration systems

- NF - Nanofiltration systems

- RO - Reverse osmosis systems

Meet or exceed USDA sanitary standards.

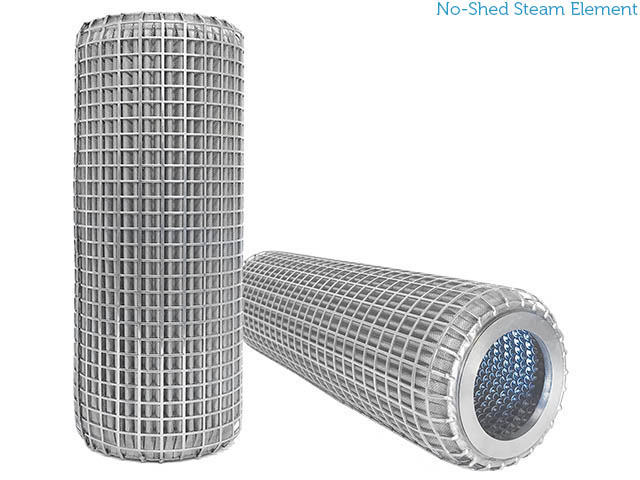

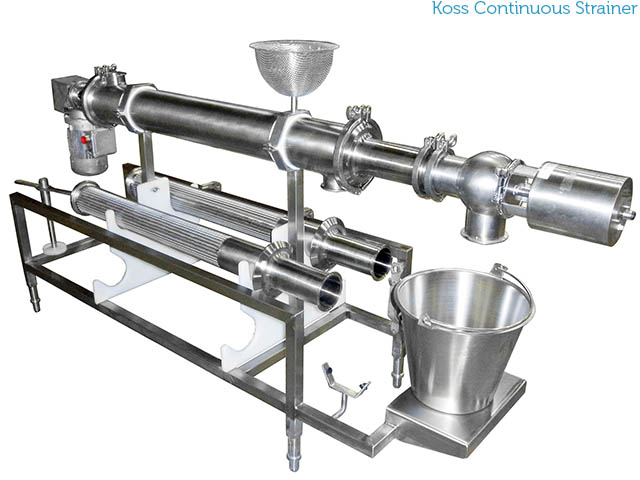

Strainers & Steam Assemblies

From rotary drum strainers, to continuous straining systems, to culinary steam assemblies, we design and build sanitary, stainless steel filtering solutions for you.

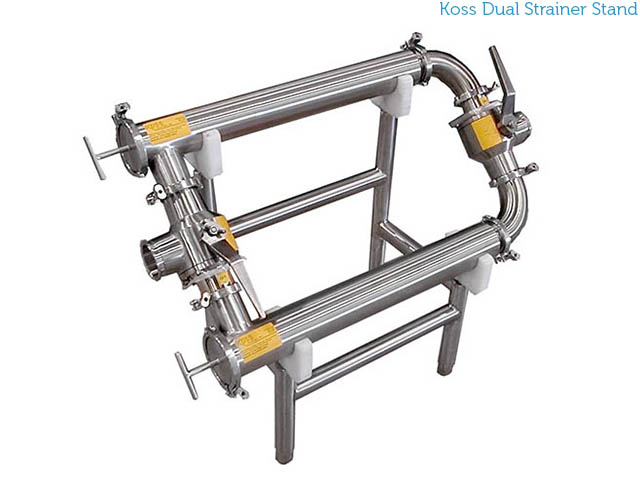

Wedge Wire Strainers & Stands

We custom-build 3-A wedge wire strainers in a variety of lengths and mesh sizes. We also engineer and build stands to meet your operational needs.