Precision Machining & Waterjet Cutting

Our skilled and experienced team takes pride in the quality and craftsmanship they add to every project.

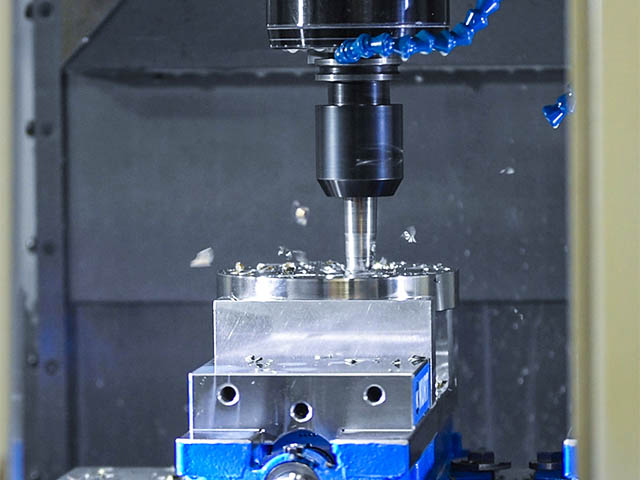

Precision CNC Machining

Pair our experienced CNC machinists with our modern, high-performance equipment and the result is accuracy, consistency and efficiency. Our capabilities include:

- Vertical machining

- Multi-spindle turning

- Live tooling

- Bar feeding

- Large stock of raw materials

- Part prototyping (one-offs)

- Production machining (longer runs)

Take advantage of our machine shop expertise.

Waterjet Cutting

Waterjet cutting combines ultra-precision and superior edge quality with a room temperature environment so there is no thermal stress on materials.

- Cut stainless steel up to 10 inches thick

- No heat = no thermal stress or tempering

- Precise cutting tolerance of .02 inches or better

- Multi-head cutting and material stacking reduces overall unit cost and increases productivity

- 4 WARDjet machines with 11 total cutting heads

- Large stock of raw materials or bring your own

Our waterjets cut a wide variety of materials including:

- Alloys

- Composites

- Foam

- Glass

- Metals

- Plastics

- Plexi-glass

- Resins

- Stone

- Tile

Waterjet cutting is ideal for:

- Machine and equipment parts

- Decorative, environmental and branded signs

- Firepit rings

- If you can draw it, we can probably cut it!

We've even cut through the wing of a fighter jet.

Equipment Capabilities

Precision CNC Machining

VF Series Vertical Mill - Small

50" x 20" x 25" travels

Taper = 40

Axis = 3

RPM = 8.1K

Tools = 20

Two mills feature shuttle tables

50" x 20" x 25" travels

Taper = 40

Axis = 3

RPM = 8.1K

Tools = 20

Two mills feature shuttle tables

VF Series Vertical Mill - Large

64" x 40" x 30" travels

Taper = 40

Axis = 3

RPM = 8.1K

Tools = 30+1

64" x 40" x 30" travels

Taper = 40

Axis = 3

RPM = 8.1K

Tools = 30+1

VF Series Vertical Mill - Large

120" x 40" x 30" travels

Taper = 50

Axis = 3

RPM = 7.5K

Tools = 30+1

Features a shuttle table

120" x 40" x 30" travels

Taper = 50

Axis = 3

RPM = 7.5K

Tools = 30+1

Features a shuttle table

Max. Turning Length = 20.9"

Max. Turning Diameter = 13.4"

Max. Bar Capacity = 2.5"

Max. Swing = 20.5"

Turret Stations = 12 with live tooling (milling)

Max. Turning Diameter = 13.4"

Max. Bar Capacity = 2.5"

Max. Swing = 20.5"

Turret Stations = 12 with live tooling (milling)

Max. Turning Length = 40"

Max.Turning Diameter = 21.5"

Max. Bar Capacity = 3"

Max. Swing = 29.5"

Turret Stations = 40 with live tooling (milling)

Max.Turning Diameter = 21.5"

Max. Bar Capacity = 3"

Max. Swing = 29.5"

Turret Stations = 40 with live tooling (milling)

Max. Turning Length = 25.9"

Max.Turning Diameter = 18.1"

Max. Bar Capacity = 1.6"

Max. Swing = 24.8"

Turret Stations = 10 with live tooling (milling)

Max.Turning Diameter = 18.1"

Max. Bar Capacity = 1.6"

Max. Swing = 24.8"

Turret Stations = 10 with live tooling (milling)

Max. Turning Length = 20"

Max. Turning Diameter = 11.8"

Max. Bar Capacity = 1.25"

Max. Swing = 23.6"

Turret Stations = 12 with live tooling (milling)

Features a bar feed

Max. Turning Diameter = 11.8"

Max. Bar Capacity = 1.25"

Max. Swing = 23.6"

Turret Stations = 12 with live tooling (milling)

Features a bar feed

Drill presses

Horizontal and other mills

Lathes

Tapping stations

Radial drills

Horizontal and other mills

Lathes

Tapping stations

Radial drills

Waterjet Cutting

Maximum cutting area = 59" x 59"

Table size = 69" x 84"

Cutting heads = 2

Hopper = 400 lb. SmartFeed

Table size = 69" x 84"

Cutting heads = 2

Hopper = 400 lb. SmartFeed

Maximum cutting area = 98" x 154.75"

Table size = 204" x 108"

Cutting heads = 3 each

Hopper = 1100 lb. pressurized bulk feed

Table size = 204" x 108"

Cutting heads = 3 each

Hopper = 1100 lb. pressurized bulk feed

Maximum cutting area = 72" x 120"

Table size = 77" x 124"

Cutting heads = 3

Table size = 77" x 124"

Cutting heads = 3

Our machines can cut 10" thick stainless steel. The thickness of other materials will depend on the material itself.

Our machine shop is your machine shop.