Membrane Systems

Ultrafiltration, Microfiltration, Nanofiltration and Reverse Osmosis Systems

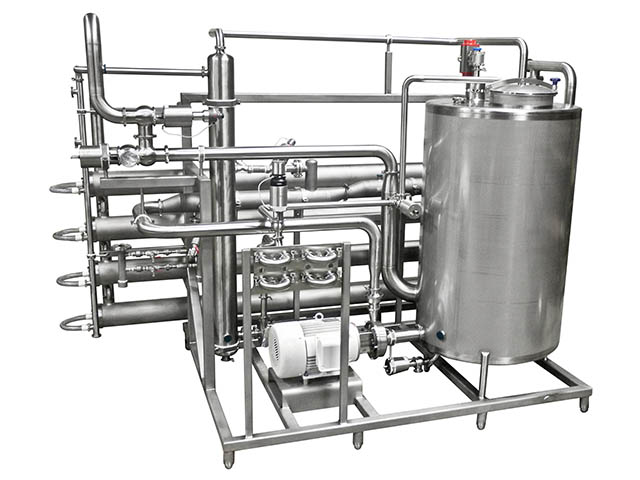

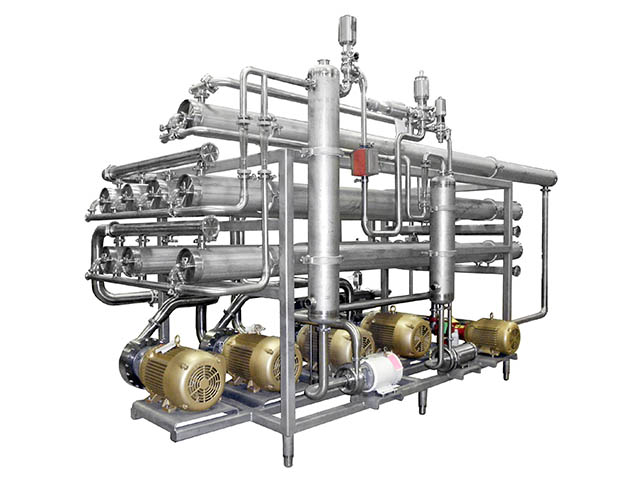

Koss Membrane Systems

Our custom-built membrane systems are optimized, designed and fabricated for your process and are available at highly-competitive prices.

- UF - Ultrafiltration systems

- MF - Microfiltration systems

- NF - Nanofiltration systems

- RO - Reverse osmosis systems

Standard features include:

- Steam bundles

- Air actuated control valves and traps

- Sanitary tanks

- Pressure pumps

- RTDs (Resistance Temperature Detector)

- Pressure and level transmitters

- Membranes

- Control panels

Meet or exceed USDA sanitary standards.

"Drop a quarter into a 5 gallon bucket of brine cleaned with a Koss ClearBrine™ UF system ... the brine is so clear you can read the date on the coin."

- JOHN KOSS

Koss ClearBrine™ Ultrafiltration Systems

Clean your brine in a Koss ClearBrine continuous UF system that outperforms both pasteurizers and UV systems.

- Pressure automatically adjusted based on the required flow rate

- All unfiltered brine is returned to the balance tank

- A small amount of concentrated, uncleaned brine is disposed of at the end of the run time

- Reduces waste / limits dumping

- Clear flex hoses on the permeate end of the membrane allow for easy visual checks of the membrane units

- Custom-built in a variety of sizes

Koss Reverse Osmosis Systems for Whey

Make whey protein concentrate using a three stage RO system from Koss. Whey concentration using reverse osmosis is often used to increase solids content and decrease volume prior to further processing or transportation.

- Total solids levels of 6-20% can be achieved

- System uses polisher vessels to clarify the permeate water

- Our RO technology will allow you to recover a large percentage of waste waters normally lost through discharge

- Polished water can be used as an initial wash throughout your facility, reducing your overall water costs and energy usage

For further reference ...

More about membrane systems

Microfiltration (MF) - Filters solids of .1 - 10 micrometers in size, like bacteria.

MF is used on process streams to remove small-diameter dispersed solids such as bacteria, fat and oil globules. Pressure is used to force water through a semi-permeable membrane with small pores. MF is often a pretreatment before ultrafiltration.

Ultrafiltration (UF) - Filters solids of .001 - .1 micrometers in size, like viruses.

UF uses membranes in which the pores are somewhat smaller than MF. Salts, sugars, organic acids and smaller peptides pass through the pores of the membrane, but viruses, proteins, fats and polysaccharides do not. A cross-flow of water prevents build up on the membrane and makes it possible to divide the feed stream into two others: a dirty water stream (retentate) and a clean water stream (permeate). UF is often used before nanofiltration or reverse osmosis.

Nanofiltration (NF) uses membranes with pores that are even smaller than UF.

Small ions pass through, but larger ions and most organic components do not. This technology is ideal for filtering out micropollutants, large salts and coloring agents, while small monovalent salts pass through. NF is used for the high-yield concentration and demineralization of products like whey. They’re also used in producing low-alcohol beverages, because the alcohol component passes through the membrane, while the color and aroma remain.

Reverse osmosis (RO) uses membranes with pores so tiny only small fractions of salts can pass through.

Certain organic compounds with low molecular weights can also pass through to a limited extent, but it is impossible for other components suspended or dissolved within the liquid (salts, sugars, etc.) to do so. RO membranes are often used to further filter streams that have already been ultra- or nanofiltered.

MF filters the largest particles (bacteria)

UF filters smaller particles (viruses)

NF filters even smaller particles (micropollutants)

RO filters the most microscopic particles