Wedge Wire Strainers & Stands

Koss wedge wire strainers are 3-A symbol authorized.

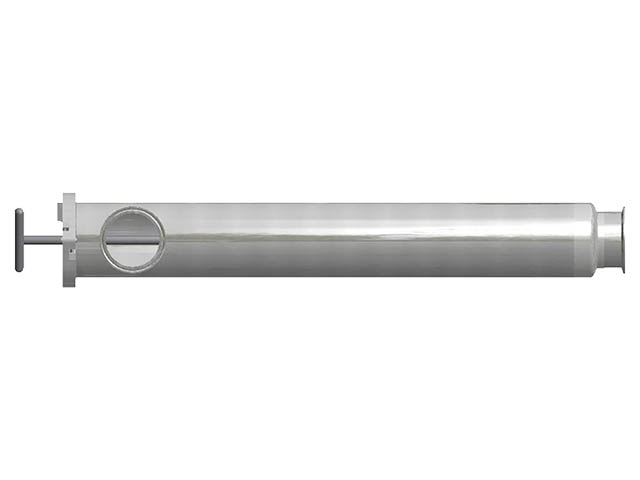

3-A Wedge Wire Strainers

Filter impurities and retain solids efficiently and economically with Koss 3-A wedge wire strainers. We build sanitary, stainless steel wedge wire strainers in both long and short lengths and multiple diameters. Features include:- 3-A symbol authorized

- 316 stainless steel body and filter element

- Sanitary ID finish of 32 μin Ra

- 4, 6 and 8 inch diameter

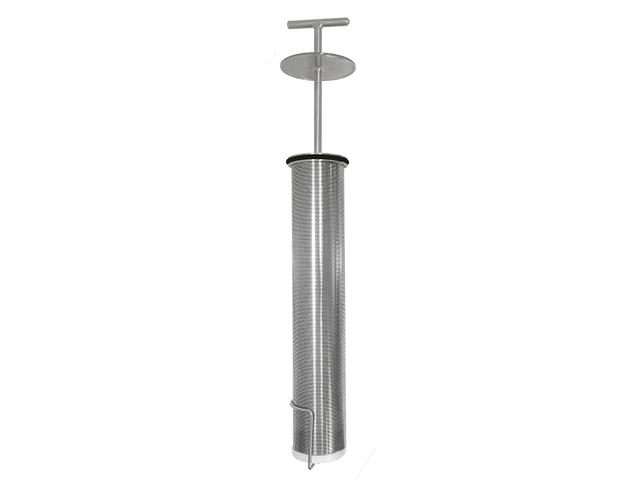

- Heavy duty mesh filter element in a variety of micron size

- Maximum temperature rating of 176°F

- Inlet placement options (side or end)

- Help maintain product integrity

- Help protect your valuable processing equipment

Click to View 3-A Certificate >

Product Literature >

See More Filters >

Automated Strainer Stands

We offer standard, manual and automated strainer stands.

Automated stands contain more than one strainer and operate using pressure sensors. When the pressure differential reaches a set point in one strainer, valves divert flow to a second strainer and an alarm is triggered signaling a need to remove and clean the first strainer.

- Fast, easy strainer removal

- Simply remove one tri-clamp to access strainer stake

- Stainless steel construction

Meet or exceed USDA sanitary standards.

Standard & Manual Stands

We build standard, no-frills stainless steel strainer stands and manual dual filter stands to meet all your process and facility needs.

For further reference ...

More about strainers and filters

Strainers are a type of filter which use perforated tubes, screen mesh or wedge wire baskets to remove larger particles from a process stream. (Think of this process as similar to using a colander for draining pasta.) Mesh is the typical measurement used in straining.

Filters remove fine particles or even microbials from a liquid or gas and include a disposable woven or non-woven “sock” or filter cartridge. (Think of this process as similar to your coffee maker filtering coffee grounds.) Microns or micrometers are the typical measurements used in filtering.

Filters and strainers can be used individually or together to remove particles from a process stream. They are ideal for the dairy, food, beverage, pharmaceutical, cosmetics and similar sanitary industries.

Strainers - remove larger particles

Filters - remove fine particles

Strainers are a type of filter