CIP (Clean-In-Place) Systems

Tell us what you're cleaning and we'll design the best CIP system for you

We know that in order to provide you with the most efficient and effective system, we need to understand your processes and your facilities.

- Is your product liquid-soluble, a solid, or somewhere in between?

- What is the shape, size, load and surface adherence of your product?

- Do you want to reuse rinse water and/or wash solutions?

- Will you need to clean multiple processes and products at the same time?

- Where are optimal valve placements for easy servicing?

- What is the best pump size based on your product line?

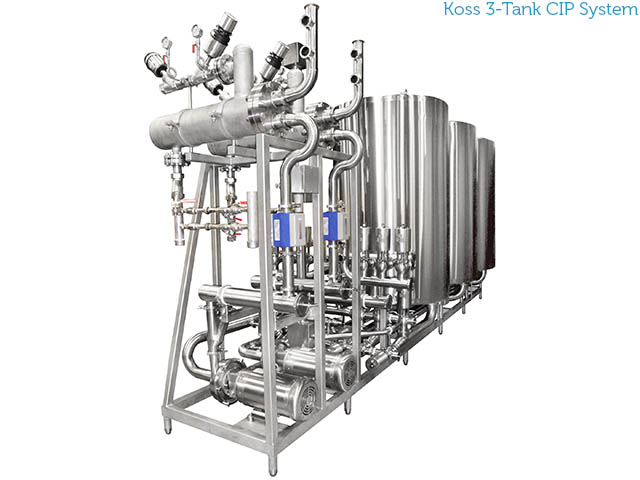

CIP Systems

We design, manufacture and install custom stainless steel Clean-In-Place systems that meet your specific process needs.

- Single-tank, two-tank and multi-tank options

- Single, dual, triple or quad operation to clean multiple circuits simultaneously

- Capacities from 50 - 3,000+ gallons

- Heavy-duty box tube construction

- Wide variety of control options

- Multiple wash programs

- Feature Koss-built stainless steel U-tube heat exchangers

- Chemical supply pumps

Meet or exceed USDA sanitary standards.

Benefits of CIP Systems

Minimize Process Cycle Time

Reduce Use of Chemicals

Lower Water & Utility Costs

Reduce Maintenance Efforts

For further reference ...

What are CIP systems used for?

CIP is a process that uses water rinses, chemicals, precise temperatures and turbulence to clean soils and bacteria from the inside surfaces of pipes, vessels, process equipment, filters and associated fittings.

It involves connecting the production line to a stand-alone flushing system. No dismantling or moving of equipment is needed.

First used in the 1950s, CIP provides increased productivity and product integrity to industries requiring high levels of hygiene including dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics.

With CIP, cleaning is faster, less labor-intensive, consistently repeatable, and poses less of a chemical exposure risk. Simple, manually-operated CIP systems can still be found in use today, but more often they are fully-automated systems with programmable logic controllers, multiple balance tanks, sensors, valves, heat exchangers, data acquisition and specially designed spray nozzle systems.

Learn About COP (Clean-Out-of-Place) >

CIP = Clean-In-Place

Flushing of equipment or system

No disassembly required