Heat Exchanger Integrity Testing

Field testing service for PHEs and Shell & Tube Heat Exchangers

Why should I do integrity testing?

Integrity Testing is a preventative field test used to identify microscopic cracks and material fatigue before they develop into harmful leaks. Ideal for plate heat exchangers and shell and tube models.

Convenient

- Unit does not need to be fully-drained, some remaining water will not affect test results

- No need to open plate packs

- Can be used on hard-to-access units

Quick

- Precision sensors pick up any discharge of gas in as little as 15 minutes per section

- No cleaning or other post-test procedures needed

Accurate

- The 5-10% hydrogen-nitrogen mix reveals flaws smaller than liquid can permeate

- The mixture has a lower probability of false positives than other tracer gases

- Automated detection system minimizes possibility of user error

- Can identify type of flaw: micro-crack, corrosion, gasket failure, etc. anywhere within your unit

Safe

- The 5-10% hydrogen-nitrogen mix is non-toxic, non-flammable, and approved for food industry use

- Does not stress or corrode plates or gaskets

Sustainable

- No helium needed (helium is a scarce, non-renewable energy source)

- Uses hydrogen and nitrogen which are sustainable, non-scarce resources which can be used without environmental harm

Product Literature >

Avoid unplanned shutdowns and unexpected downtime

Avoid damaged product and product loss due to leaks

Schedule service and maintenance to suit your business needs

Proactive approach provides confidence in your equipment

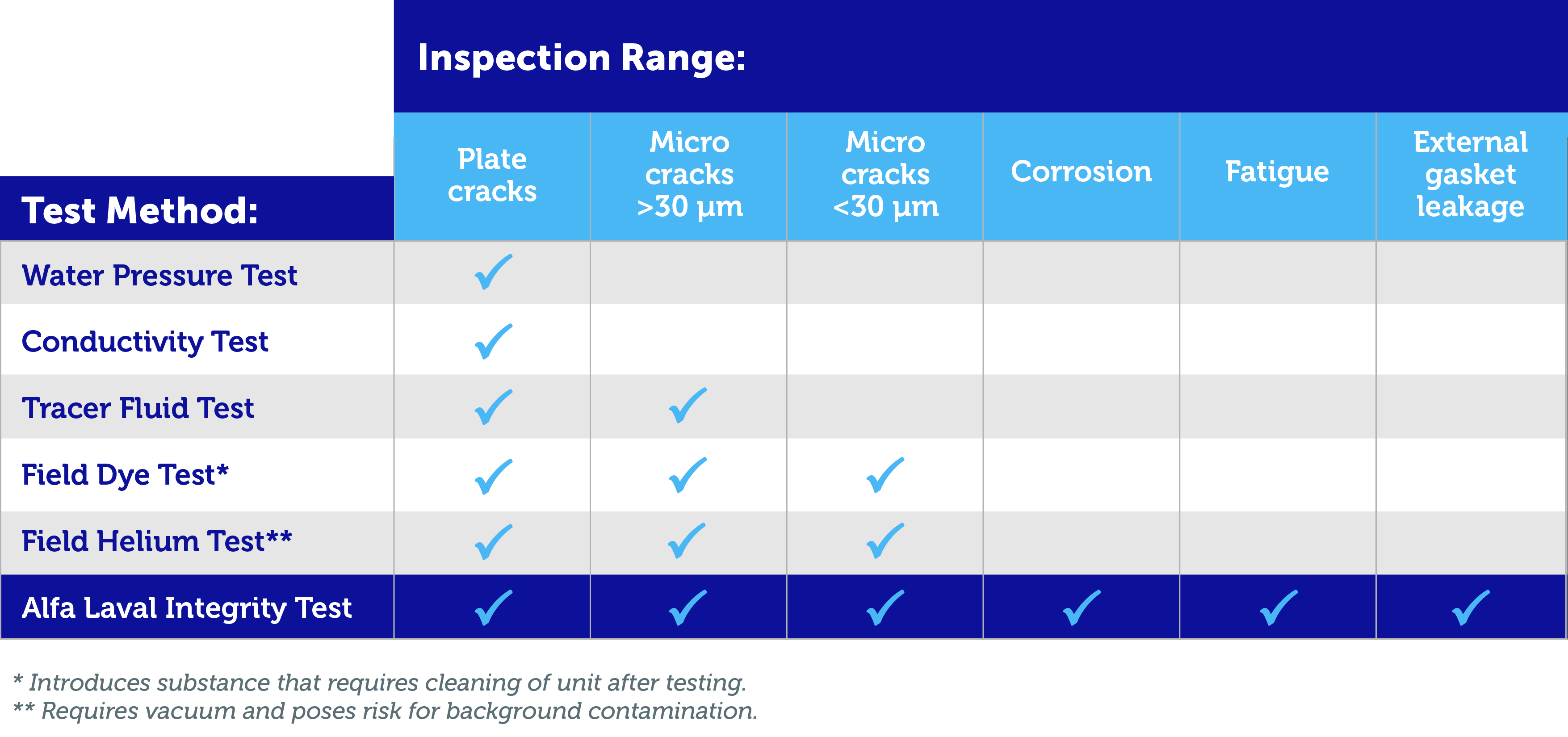

Integrity Tests vs. Other Methods

Comparison of Testing Methods

PHE Integrity Testing offers more robust results with a greater level of detail than other standard plate heat exchanger testing methods.

Contact us to schedule your integrity test today.