Strainers & Steam Assemblies

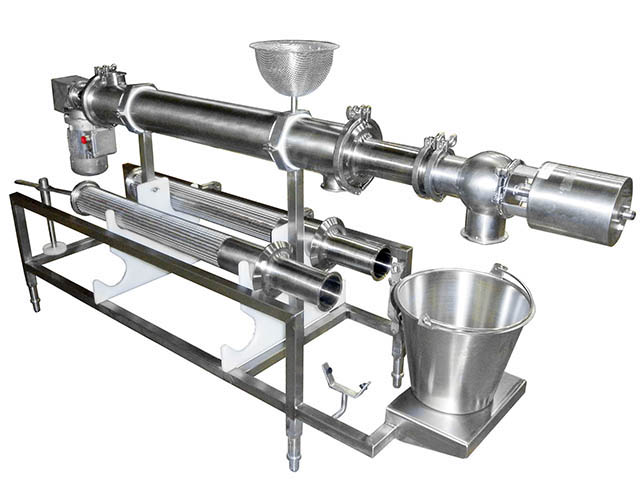

Continuous Straining Systems

Want to increase efficiency of your process cheese line? We’ve designed a continuous strainer which removes particulates from process cheese after it’s been cooked. This little system can make a big impact on your productivity by drastically reducing the number of necessary sock changes upstream.

- Skidded system

- Heavy-duty stainless steel

- Reduces downtime by limiting the maintenance of clogged sock filters

- Small foot print: roughly 8' by 2.5' and standing less than 4' tall

Meet or exceed USDA sanitary standards.

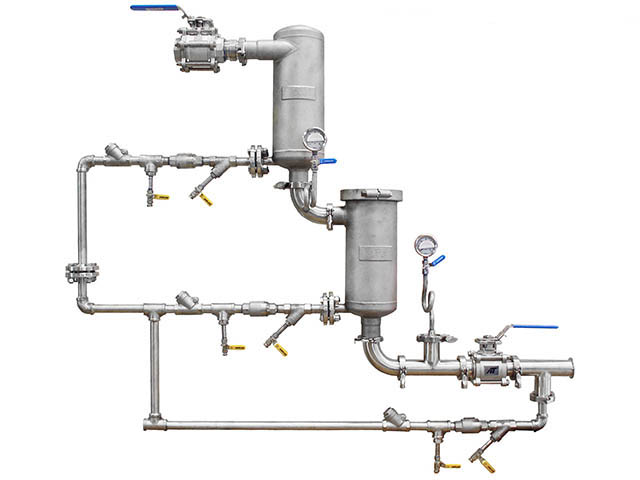

Culinary Steam Assemblies

Does steam come into direct contact with your food product? Improve overall product quality with a steam assembly from Koss.

- Capable of removing 95% of particles two microns or larger

- Filtered steam will result in a purer end product

- Custom fabricated from stainless steel

Meet or exceed USDA sanitary standards.

Meet 3-A Accepted Practices requirements.

Rotary Drum Strainers

Our custom rotary drum strainers are used to separate and sieve particles from product streams and are mainly used in situations with a high water flow and relatively small load of solid particles. Our strainers are stainless steel and ideal for a variety of applications. The rotating filter drum is continuously cleaned by a steam header and rotation against a scraper blade. Benefits of a rotary drum strainer include:

High throughput

- Continuous operation

- Low operating costs / low energy input required

- Sturdy construction

- Wide range of applications due to stainless steel

- Direct sludge outlet into drainage container

- Can serve as a single-service CIP system for a brine environment

Meet or exceed USDA sanitary standards

For further reference ...

More about culinary steam

There are several ways to describe steam used in processing. Culinary steam can be direct injected or infused during food processing. Culinary steam needs to meet 3-A culinary standards as it can, and often does, come in direct contact with the food product.

Process steam is used in process applications as a source of energy for process heating, pressure control and mechanical drives. It does not generally come in contact with the final product.

Different than process steam

Often is in direct contact with food

Must meet 3-A standards

More about rotary drum strainers

Rotary drum strainers consist of a large rotating wedge wire strainer within a stainless steel chest. Water passes through the screen and drains into a reservoir to be pumped for further processing. Solids are retained on the outside of the screen and are rotated toward a scraping blade. The blade removes the particles stuck to the outside of the screen which prevents build up and clogging.

Rotary drum strainers are used for a variety of applications including wash water for vegetables with fibrous waste of roots and leaves, or for separting curds from whey in cheesemaking.

Rotating strainer within a steel chest

Strains with the use of water

A scraping blade prevents clogging